CLEAN ENVIRONMENTAL PROTECTION:

SAFE STORAGE OF ALUMINIUM CHIPS

Aluminium chips have always been stored in our warehouse in two specially sealed boxes. However, these swarf also contain water containing emulsion, which was used for cooling purposes during drilling and milling. These dripping residues are caught and then collected in an underground tank.

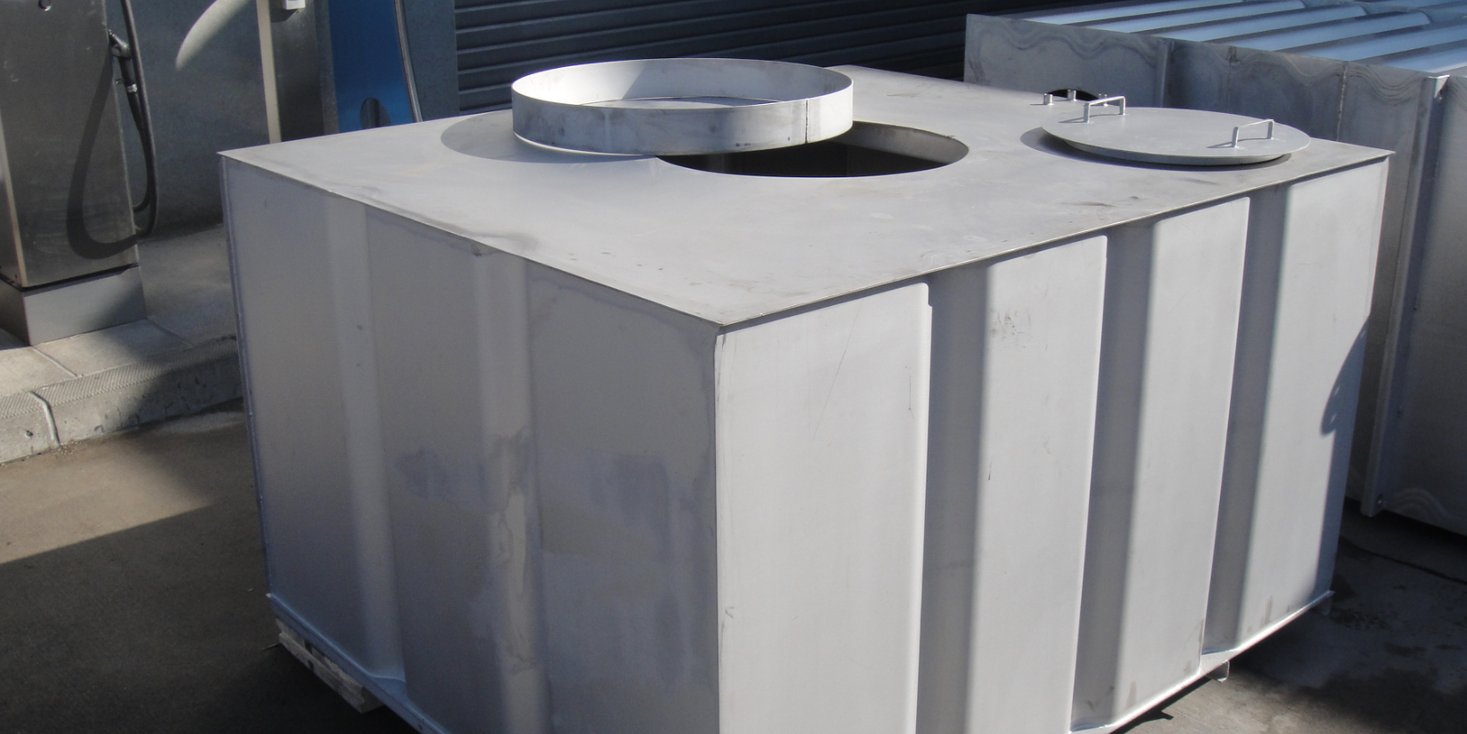

A sustainable modernisation of the entire system was on the agenda. Therefore, a complete reconstruction of the storage areas was carried out. First, the massive concrete ceilings to the old tanks were cut open. Double-walled stainless steel tanks with a capacity of 2.8 and 3.4 cbm were installed in these pits. In addition, an above-ground double-walled stainless steel tank with a capacity of 7.3 cbm was installed in Hall 1. The double-walled tanks are constantly monitored by means of a high-pressure leak detector. An overfill protection device is used to prevent overfilling.

Furthermore, a leak detector was installed in the free spaces between the stainless steel tank and the concrete pit. Thus, the original pits now additionally serve as a control device. The pipe to the tanks as well as the suction pipes were also laid in double-walled stainless steel pipes and are monitored by high-pressure leak detectors.

In order to free the stainless steel tank from any mechanical impact and forces, specially configured concrete slabs were poured according to the static requirements, which were laid on top of the existing construction all around without even touching the new storage tank. In addition to the remaining concrete and the geomembranes underneath, a full-surface steel catch basin with a thickness of 15 mm laid on top of the concrete serves as a leak-proof construction. Circular steel collars in the area of the tank dome serve as the inlet construction. To secure the adjacent traffic area, a bend to the storage area was installed by means of a steel sleeper. A subsequent leak test of the weld seams was carried out with a vacuum bell at a negative pressure of 600 mbar. The same applies to the piping of the overfill protection devices, leak detectors as well as control devices.

In order to properly accommodate all these techniques, extra central monitoring stations were built for this purpose, which are within easy reach and have additional control equipment [visual and acoustic alarm] as well as being extremely easy to maintain and check.

The system thus renewed complies with the requirements of the Water Resources Act and even exceeds them in some areas. The goal, namely the "preservation of soil and groundwater from harmful and water-polluting substances", has been more than achieved.